Heat Pump Systems

A heat pump is essentially a reverse cycle air conditioner. It can move heat from indoors to outdoors, or it can do the opposite, and extract heat from the outdoor environment to heat the interior. With a traditional split system furnace and AC, the indoor unit is referred to as the evaporator coil and the outdoor unit as the condensing coil. With heat pumps, the function of each coil depends on the operation mode of the system, heating or cooling. When the system is in cooling mode, the functions are the same as with a straight cooling split system. In heating mode, the indoor coil becomes the condenser and the outdoor coil is the evaporator. Therefore, with heat pumps the coils are simply referred to as indoor and outdoor.

The most common type of heat pump is one that transfers heat from air to air. Other types of heat pumps are water source and ground source. The outdoor coil of a water source heat pump could be in the bottom of a lake or pool. This article will focus on the most common type of heat pump, air to air. Heat pumps include additional equipment that is not found in cooling only split system units. The outdoor unit contains an accumulator and a reversing valve which are not found in split system AC units. The indoor air-handler of a heat pump is often accompanied by electric strip heaters. Heat pumps also contain a filter-drier to prevent contaminates from flushing through the system.

The reversing valve is the key component that determines the mode of operation of a heat pump. It contains a piston or slide that is activated by a solenoid, and four pipes. The direction of refrigerant from the compressor does not change. The high pressure line from the compressor enters the reversing valve, which determines whether the indoor or the outdoor coil will act as the condenser. In one position, the valve will direct the high pressure line to the outdoor unit, and in another position, it will direct the high pressure line to the indoor unit. The pipe in the center is the suction line that returns to the compressor, and depending on the position of the valve it is connected to the pipe from either the indoor or outdoor coil.

Heat pumps have a suction line accumulator to prevent liquid refrigerant from entering the compressor. In heating mode, the outdoor coil (functioning as an evaporator) might not be able to fully vaporize the refrigerant. The accumulator collects the liquid refrigerant and protects the compressor. It is a large cylinder that can be found near the compressor. Because these components must be matched with the particular compressor type and size of the system, a traditional split-system condenser cannot successfully be field-modified to convert it to a heat pump.

A heat pump inspection involves the same procedures as AC inspections, except that the heat pump need only be tested in one mode - if it works in heating mode it will work in cooling mode. If the inspection takes place on a cold day, it should be tested in heating mode, and on a warm day, in cooling mode. The only item that would be tested by operating it in both modes during an inspection would be the reversing valve itself. When a heat pump is tested in heating mode, the sensible temperature of the air from the registers might feel cool, because it will be less than body temperature. The air temperature might be in the 80's or low 90's. Though it feels cool to the touch, air at such temperatures will warm the house.

As the outdoor temperature drops lower, two other factors come into play with heat pumps. The balance point of a heat pump is the point where the outdoor temperature has dropped so low that the heat pump cannot supply the conditioned space with sufficient heat. At that time, supplemental strip heaters are activated to supply electric-resistance heat indoors. Some heat pumps are designed with a gas or oil furnace as the backup heating mode, though strip heaters are much more common. Strip heaters are sometimes arranged so as to come on in stages, depending on the conditions at the time of use.

During extreme cold weather or a large difference between the thermostat setting and the room temperature, all the strip heaters will activate. Heat pumps also might experience icing of the outdoor coil during the heating mode. When this occurs, the heat pump goes into defrost mode by reversing direction. During such time, the system is trying to provide cool air to the interior, so the supplemental electric resistance heaters will activate to maintain a warm air flow.

Heat pump thermostats will typically have an "emergency heat" setting. In such a mode, the electric strip heaters will be turned on and override the other settings of the system. During emergency heat mode, the air from the registers will feel warmer than in ordinary heating mode. When testing a heat pump in heating mode, inspectors should be careful not to turn the thermostat too high, or they may activate the emergency heat and not be able to accurately test the heat pump function.

Heat pumps are far more economical than pure electric resistance heat. Electric heat generates 3.413 Btu's per watt. The efficiency of heat pumps is measured in terms of the coefficient of performance (COP) and will be at least twice that of electric resistance heat.

Almost all heat pumps include a crankcase heater to prevent excess migration of oil and/or liquid refrigerant to the compressor. If the unit has not been turned on for the required amount of time - typically 12 to 24 hours - the compressor could be damaged. Inspectors encountering a heat pump where the breaker or switch is turned off should not operate the system.

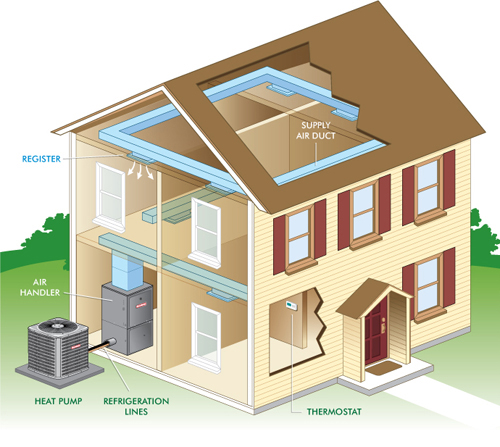

Most heat pumps will have an air handler and a duct system. However, heat pumps can also be self contained units mounted in a wall (such as those found in hotels) or they could contain a wall-mounted indoor coil and blower with a separate outdoor coil and refrigerant tubing between the two (commonly marketed as "ductless" units).